Can WAAM Parts Be Certified? What Standards Apply?

Wire Arc Additive Manufacturing (WAAM) is no longer just a prototyping tool, it’s being used to produce functional, load-bearing, mission-critical parts. But in regulated industries like energy, maritime, and defense, there’s a crucial question every procurement team or QA engineer eventually asks: can WAAM parts be certified? The answer is yes—WAAM parts can meet the […]

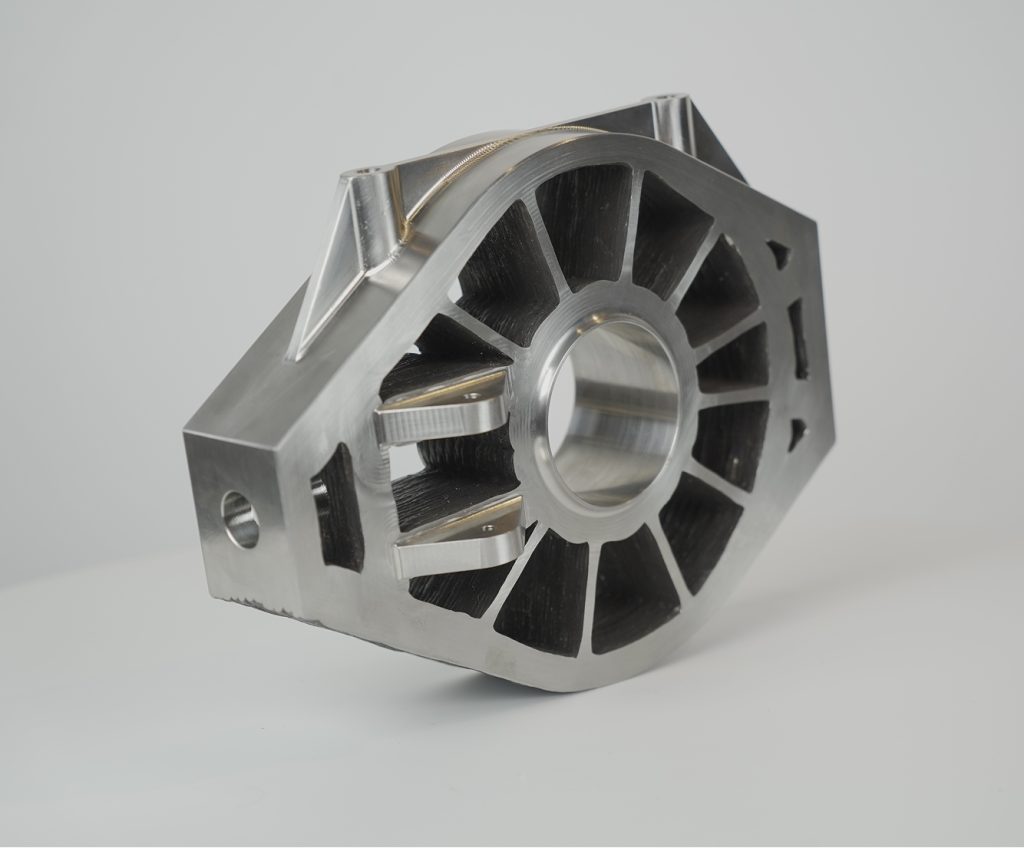

BMW GROUP

MX3D is proud to share that BMW Group employed their M1 Metal AM System and proprietary software MetalXL to 3D print automotive components. BMW Group demonstrates how additive manufacturing, specifically wire arc additive manufacturing (WAAM), can provide valuable solutions for an industry such as automotive. Their engineers succeeded in proving that it is possible to […]

How Is 3D Printing Transforming Automotive Spare Parts and Tooling?

Automotive manufacturing has always been about speed, scale, and precision. But in today’s rapidly changing supply chain environment, automakers are looking for ways to stay flexible, reduce costs, and accelerate development. That’s where additive manufacturing (AM), particularly large-scale metal 3D printing like Wire Arc Additive Manufacturing (WAAM), is making a real impact. From tooling and […]

How Does WAAM Material Compatibility Compare to Other 3D Printing Methods?

Choosing the right additive manufacturing process often starts with one key question: “Which materials can I use?” When it comes to metal 3D printing, different technologies offer very different answers. Some processes are limited by the need for finely atomized metal powders. Others require specific alloy formulations to perform reliably. But Wire Arc Additive Manufacturing […]

How Do You Design Parts for Wire Arc Additive Manufacturing (WAAM)?

As Wire Arc Additive Manufacturing (WAAM) continues to grow in industrial applications, one question consistently arises from engineers and designers alike: “How should I design parts specifically for WAAM?” Designing for Additive Manufacturing (DfAM) is already an evolving discipline, but WAAM adds its own layer of complexity and opportunity. Unlike powder-bed systems, WAAM is capable […]

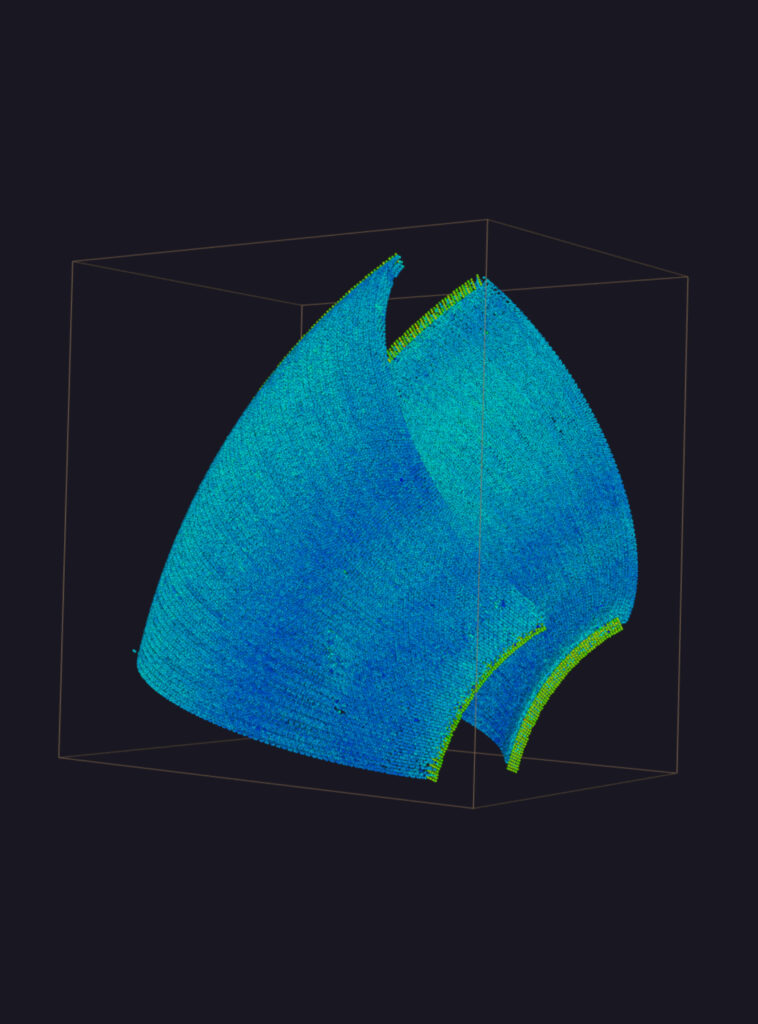

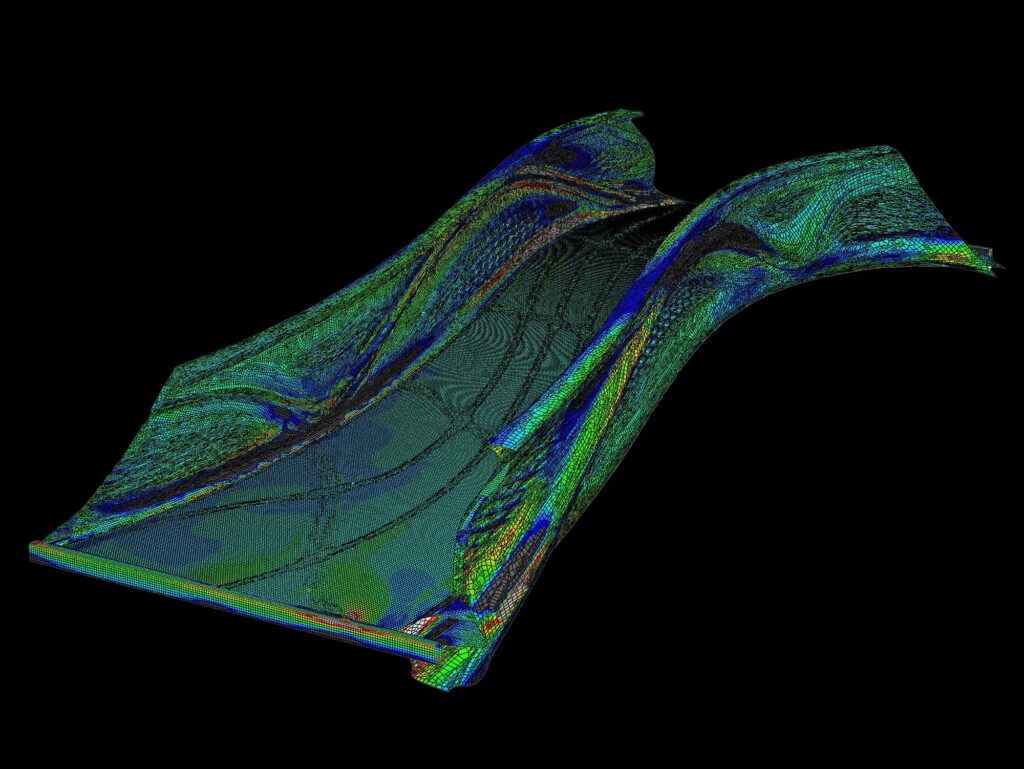

How Accurate Is WAAM? Understanding Tolerances in Wire Arc Additive Manufacturing

When it comes to additive manufacturing, accuracy isn’t just a technical metric; it’s often the deciding factor in whether a printed part can replace a machined or cast component. For engineers evaluating Wire Arc Additive Manufacturing (WAAM), one of the first questions is usually, “How precise is it?” WAAM is known for its ability to […]

Can Additive Manufacturing Help Automakers Build Lighter, More Efficient Vehicles?

Reducing vehicle weight has always been one of the most effective ways to improve fuel efficiency, boost performance, and lower emissions. But until recently, cutting weight often meant sacrificing manufacturability, adding cost, or compromising strength. With the rise of additive manufacturing, especially large-format metal printing like Wire Arc Additive Manufacturing (WAAM), that equation is changing. […]

News Lloyd’s Register awarded MX3D a certification for their directed energy deposition (DED-Arc) facility, incorporating the M1 Metal AM system

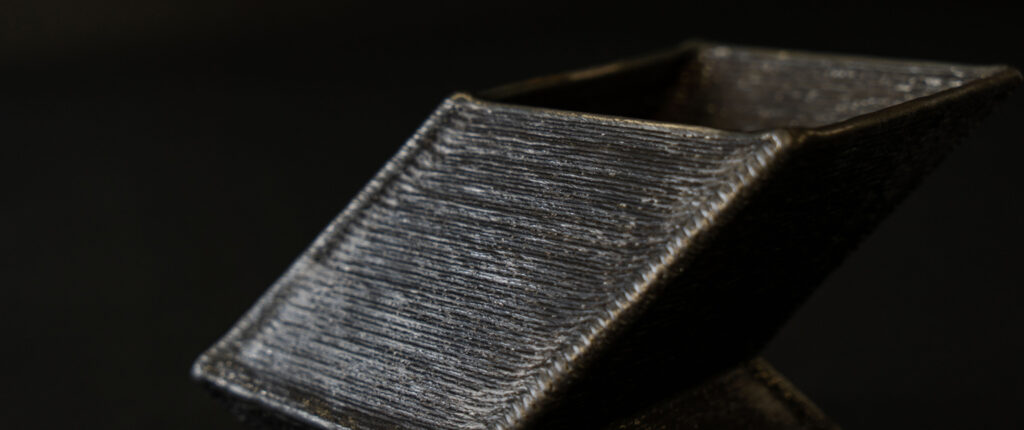

Gradient Screen

This experimental sculptural work, produced by MX3D and designed by Joris Laarman, is part of a collection of sculptural screens in varying sizes, geometries and materials. Even multi-material gradients from bronze to steel are in the planning. The computational generated esthetics of the screens are not just pleasing for the eye but are also pushing the […]

Cucuyo Bar

MX3D is proud to deliver ‘Cucuyo’ to STARR Catering Group. Cucuyo will be used as an outdoor bar at the Perez Art Museum Miami (PAMM). The work was made in collaboration with Miami base architects BBA . The bar will be installed early September. The official opening will be on 27th of September. Named after summer childhood […]