Materials You Can Trust

Our Materials

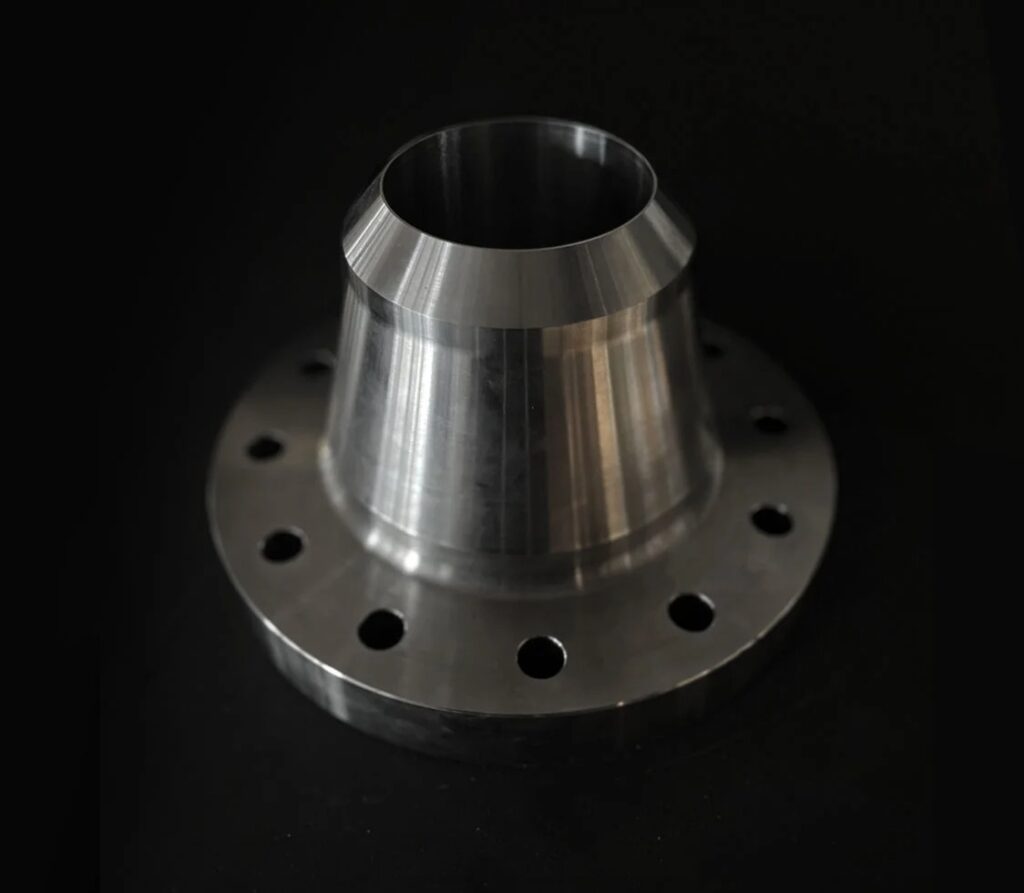

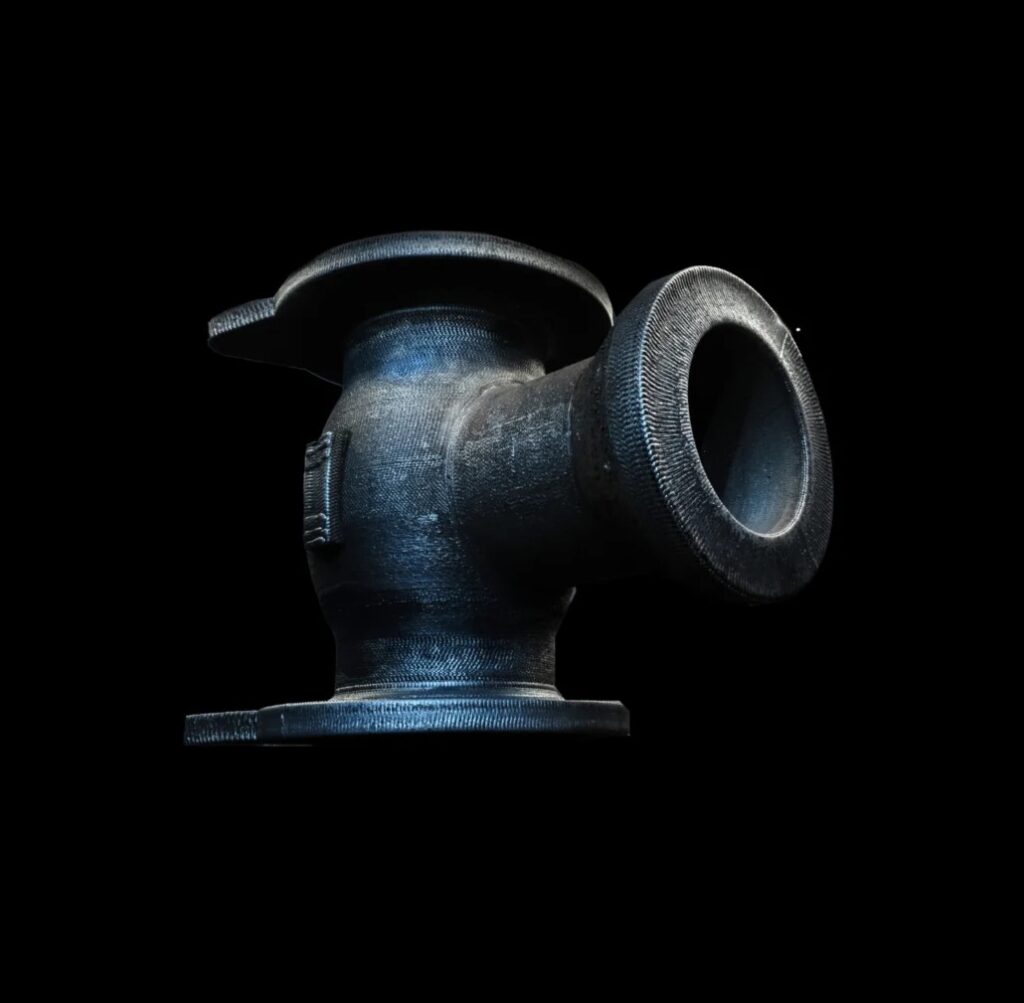

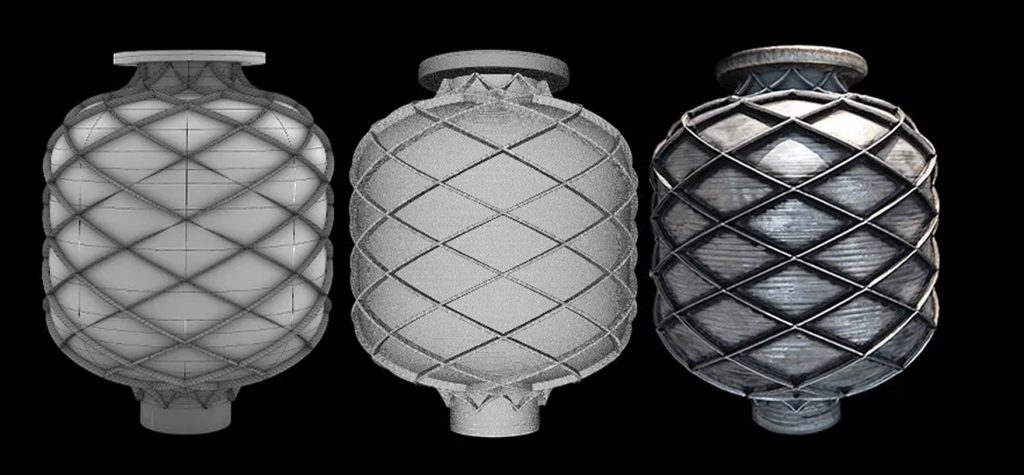

Welding Wires 3D print Large Parts

MX3D’s Tech is based on welding science. We work with a wide range of weldable metals and alloys. This ranges from stainless steels, duplex, Inconel, to aluminum, bronze, and corten alloys. In short, most weldable materials can be processed with our WAAM technology. Below is a list of commonly used materials. If you would like to inquire about other materials, please reach out to us.

Our Alloy Range & Material Expertise

Aluminum

- 2319: EN ISO 18273: S AI 2319 (AlCu6MnZrTi)

- 5356: EN ISO 18273: S Al 5356 (AlMg5Cr(A))

- 5183: EN ISO 18273: S Al 5183 (AlMg4,5Mn0,7(A))

- 4018: EN ISO 18273: S AI 4018 (AISi7Mg)

- 4046: EN ISO 18273: S AI 4046 (AISi10Mg)

- 6063: EN ISO 18273: S AI 6063 (AlMg0.7Si)

Bronze & Copper

- CuSn6: EN ISO 24373: Cu 5180A

- CuSi3 : EN ISO 24373: S Cu 6560

- CuAl8: EN ISO 24373: S Cu 6100

- CuAl8Ni6: EN ISO 24373: S Cu 6328

- CuNi 70/30

Stainless Steel

- 308LSi: EN ISO 14343 – A: 19.9LSi

- 316LSi: EN ISO 14343 – A: 19.12.3LSi

- Duplex 2209 and 2205

- Superduplex 2594

- Matersitic 410NiMo

- Precipitation hardening 17-4PH

Steel

Mild steel

ER70S-6: EN ISO 14341-A: G 46 4 M G4Si1

ER80S-D2: EN ISO 14341-A: G 50 7 M 21 4Mo (higher strength/low-alloy)

ER80S-Ni1: EN ISO 14341-A: G 50 6 M 21 3Ni1 (improved low-temp toughness)

ER80S-Ni2: EN ISO 14341-A: G 50 7 M 21 2Ni2 (Ni alloyed)

High-strength steel

- NiMo: EN ISO 16834-A: G Mn3Ni1Mo

- NiCrMo: EN ISO 16834-A: G Mn3Ni1CrMo

ER100S-G: AWS A5.28 – EN ISO 16834-A: G 62 4 M13 Mn3NiCrMo

ER110S-G: AWS A5.28 – EN ISO 16834-A: G 69 4 M21 Mn3Ni1CrMo

ER120S-G: AWS A5.28 – EN ISO 16834-A: G 89 4 M21 Mn4Ni2CrMo

Other steel alloys

- Maraging Steels

- Tool Steels Fe3 and Fe8

Benefits of Wire

Most materials supplied as a wire for arc welding are compatible with WAAM. This gives WAAM access to one of the broadest ranges of materials for metal AM on the market. Moreover, compared to metal powders, weldable wires are more affordable, accessible, and available worldwide in general.

Within MetalXL, you are in the lead regarding material development and are able to build new strategies for your specialty wire and expand on existing ones when your standard or geometry requires this.

Outside of the range of materials presented, we also print with other materials.

Other alloys

- Inconel 625 and 718

- Other materials on request

Key industry standards & qualifying partners

Certifications & Industry Standards

Value Adding Standards

Our range of certifications and industry standards is continuously expanding. We have been successfully audited for the Lloyds AM facility Certification, API20S by Fieldnode, ISO9001 by DNV, and actively pursue new qualifications. As new applications demand specific qualifications, we ensure our technology is compatible & compliant and our QMS stays up to date. This way, MX3D ensures that every new partnership, system, and production challenge can meet the right standard. Our team of IWE, international welding engineers, is ready to help you qualify your project.

Featured

Materials & Standards in Action

Curious how our materials and industry standards work in practice? Explore our cases and see MX3D’s certified WAAM technology in action across critical industries.

Kevin

Get in touch

Do you have a question about materials or qualifying projects? We are up to the challenge. Please reach out to Kevin or send us an email through our contact form.

Kevin Affari

WAAM Expert

Why This Matters

Flexibility

Print in commonly used industrial alloys, tailored to your supply chain

Reliability

Confidence that parts will meet or exceed forged/ cast benchmarks

Authority

Certified, traceable, and ready for mission-critical applications