Wire Arc Additive Manufacturing (WAAM) is increasingly being adopted for industrial, load-bearing applications. To further expand its material portfolio, MX3D has successfully validated super duplex stainless steel (ER2594) for WAAM, targeting demanding environments such as offshore, maritime, energy, and chemical processing. The wire used for testing was supplied by our partner NovaMetal.

To confirm production readiness, MX3D conducted an extensive qualification program together with the Belgian Welding Institute (BWI), covering bend testing, tensile testing, impact testing, and radiographic inspection on both 5 mm and 50 mm WAAM-printed sections.

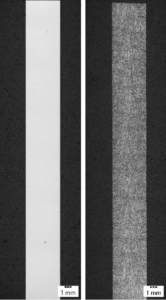

Bend Testing: Ductility Across Thin and Thick Sections

Bend tests were performed in accordance with ASME BPVC Section IX.

- Both the 5 mm and 50 mm specimens were bent to 180°, applying the required elongation levels defined by the standard.

- Visual inspection showed no cracks or surface imperfections in any of the samples.

These results confirm consistent ductility and sound interlayer bonding, even in thick WAAM-printed super duplex components.

Tensile Testing: Strength and Elongation Confirmed

Tensile testing followed ISO 6892-1 (Method A), with specimens taken perpendicular to the WAAM build direction.

- The 5 mm specimens showed yield strengths around 550 MPa, tensile strengths around 760 MPa, and elongation values exceeding 30%.

- The 50 mm specimens demonstrated even higher strength levels, with yield strengths around 580 MPa, tensile strengths up to 850 MPa, and elongation values around 35%.

All results were classified as acceptable, demonstrating stable mechanical performance across section thicknesses.

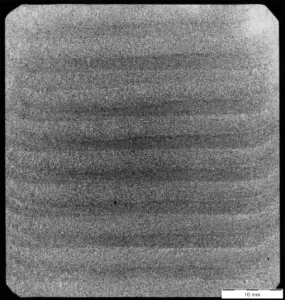

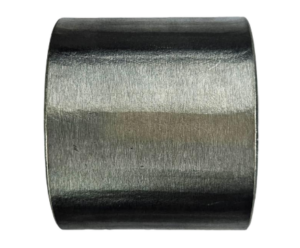

Macroscopic examination

Microscopic examination confirmed a uniform duplex microstructure with no abnormal phases or interlayer defects, indicating stable WAAM processing and supporting the measured mechanical performance.

- 5 mm

- 50 mm

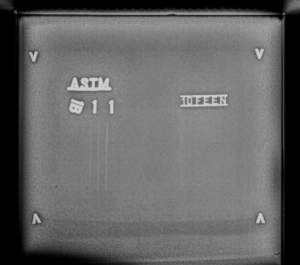

Impact Testing: Toughness Far Beyond Requirements

Charpy V-Notch impact tests were performed on 50 mm WAAM super duplex samples at –40 °C, in accordance with ASTM SA-370 and ASME BPVC Section IX.

- The required minimum impact energy was 27 J. Measured values ranged from approximately 94 J to 158 J, with an average well above 100 J.

- A representative value of 119 J clearly illustrates that the WAAM material exceeds the requirement by a wide margin.

These results confirm excellent low-temperature toughness for WAAM-printed super duplex.

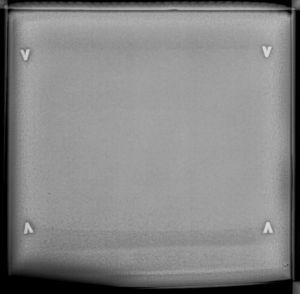

Radiographic Inspection: Internal Quality Verified

Radiographic (X-ray) inspection was carried out on both thin and thick WAAM sections. The inspections confirmed a high internal material quality, comparable to that of cast or forged super duplex components, with no critical defects detected.

What This Means for Industrial WAAM

The successful qualification of super duplex stainless steel demonstrates that WAAM can deliver high-strength, corrosion-resistant, and tough components at an industrial scale.

With proven performance across mechanical testing and inspection, WAAM-printed super duplex is well-suited for offshore, maritime, energy, and chemical processing applications, offering a robust alternative to conventional manufacturing methods.